Tel:

Email:

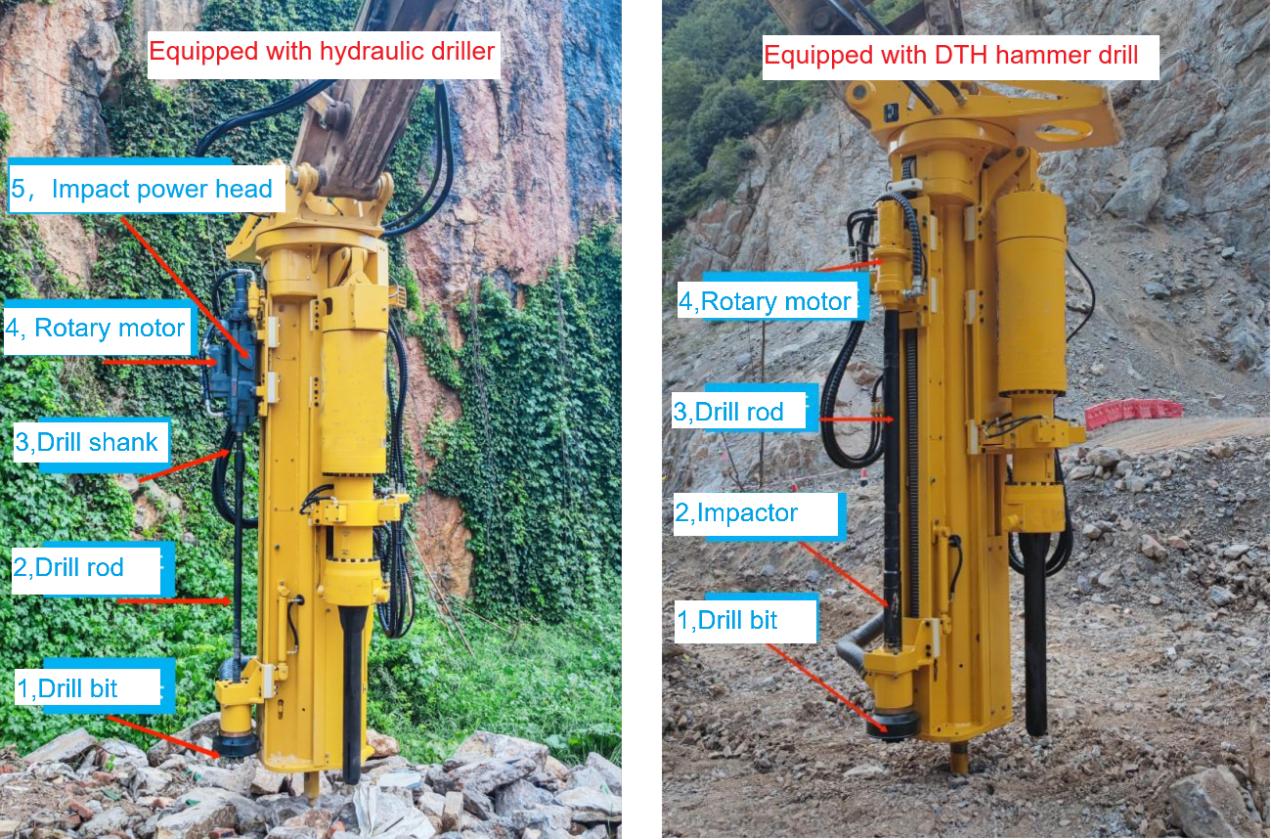

Equipped with hydraulic driller | Equipped with DTH hammer drill | |

Consumable Types | Drill bit, drill rod, shank, drill rig copper sleeve, O-ring, | impactor, drill bit. |

Impact Location | The impact power head is located at the upper end of the drill rod. | The impactor is located at the lower end of the drill rod. |

Drill Rod Load | The drill rod needs to transmit both impact power and torque, resulting in a heavy load. | The drill rod does not need to transmit impact power, only torque, resulting in a light load. |

Borehole Diameter | <115mm | >135mm |

Drill Rod Diameter | 51mm | 89mm |

Drill Rod Service Life | (Granite Working Conditions) | Over one year |

Shank Service Life | Approximately 30 days | No shank required |

Driller Regular Maintenance | Copper sleeves, O-rings, seals, nitrogen pressure, etc. | Almost no maintenance required |

Driller Stability | Relatively stable | Extremely stable |

Air Compressor | 4m³ fully hydraulic screw compressor | 15-18m³ fully hydraulic twin-screw compressor |

Splitting Effect | The larger the borehole diameter, the better the overall splitting effect. | |

Splitting Service Life | The larger the borehole diameter, the longer the service life of the splitting wedges. | |

The drilling process consists of three components: impact, rotation, and debris removal. First, the drill bit crushes the rock through impact, while simultaneously rotating to break up the crushed rock. At the same time, compressed air blows the fragmented rock out of the borehole. All drilling rigs must incorporate these three components.

In hydraulic drills, both the impact and rotation components are located at the upper end of the drill rod, which is why they are also known as top hammer hydraulic rock drills. The impact power head transmits kinetic energy to the drill bit through the drill rod. Since the drill rod must transfer this kinetic energy, its diameter is relatively small, typically 51mm. During hard rock drilling, the drill rod continuously wears out while transmitting kinetic energy. Due to its small diameter, the failure rate is relatively high. Under granite working conditions, a drill rod typically breaks every 2–3 days. When replacing a broken drill rod, the drill bit must also be replaced simultaneously, as broken drill rods make it extremely difficult to remove the old bit.

The hydraulic drills equipped on integrated drilling and splitting machines typically bore 115mm diameter holes and require high-power hydraulic rock drills with a power rating above 22kW. However, importing a single high-power hydraulic drill costs over 58,000 USD, which is prohibitively expensive. Domestic high-power hydraulic drills are currently imitations of foreign models, but due to relatively immature technology, their stability is significantly inferior despite the lower price. Since integrated drilling and splitting machines are often used in hard rock conditions, the failure rate of hydraulic rock drills is relatively high.

In contrast, DTH (Down-the-Hole) hammer drills have a simpler structure and much lower technical requirements. The entire range of domestic DTH hammer drills is now highly mature, offering exceptional stability in daily use with almost no failure rate, enabling continuous 24-hour non-stop operation.

Hydraulic drills require consumables such as drill bits, drill rods, shanks, and copper sleeves. Since hydraulic drills rely on the shank and drill rod to transmit impact force to the drill bit, the load on the drill rod and shank is particularly high during drilling in hard rock conditions. For example, when drilling granite, a drill rod typically breaks every 2–3 days on average. Since the drill rod and drill bit are connected with a reverse thread, it is almost impossible to remove the drill bit from a broken drill rod segment. Therefore, both the drill rod and drill bit must be replaced simultaneously, leading to significantly higher consumable costs.

In contrast, DTH hammer drills have their impactor located at the lower end, eliminating the need for a shank. The drill rod does not transmit impact force, allowing for a larger diameter and a service life measured in years. As a result, the only regular consumable for DTH hammer drills is the drill bit.

Currently, domestic hydraulic drills can only reliably drill holes within 115mm, whereas DTH hammer drills can drill holes exceeding 135mm. The splitting wedge, the core component of a rock splitter, has a longer service life and lower consumable cost when its diameter is larger. Additionally, larger-diameter splitting wedges provide better splitting performance.

For more infos of drilling and splitting integrated machine, contact us please. www.sc-equipment.com