Tel:

Email:

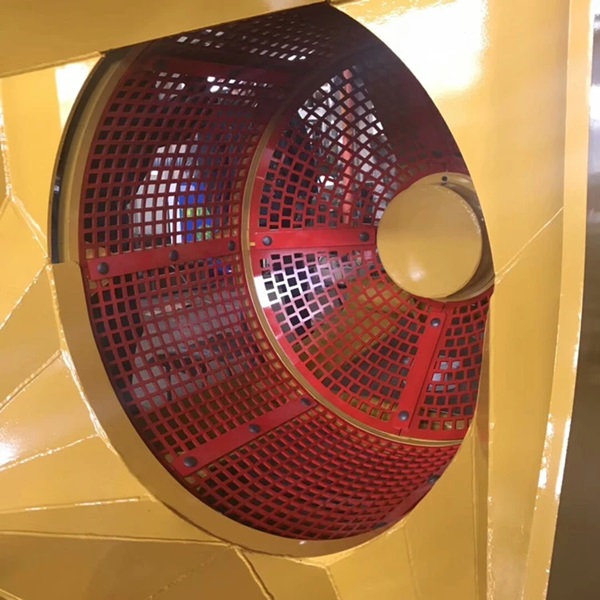

On modern construction sites, time and efficiency are critical factors that determine project success. A rotating screening bucket has become a transformative attachment, allowing operators to separate and sort materials directly on site without the need for additional equipment. By reducing transport requirements and enabling instant reuse of screened materials, this attachment streamlines workflows and lowers overall costs. With companies like SC Equipment focusing on research and innovation since 2008, rotating screening buckets are engineered to meet the evolving needs of today's construction professionals.

The greatest strength of a rotating screening bucket lies in its adaptability. Whether dealing with soil, sand, demolition waste, or aggregates, the attachment provides consistent results across diverse materials. This flexibility makes it indispensable for landscaping, road construction, recycling projects, and utility works. SC Equipment integrates advanced R&D with strict material standards to ensure their buckets can endure tough operating environments while maintaining precise screening efficiency. For contractors, this means one tool can replace multiple processes, saving both time and equipment costs.

The design of a rotating screening bucket is centered around maximizing output while minimizing effort. High-quality materials and robust manufacturing deliver durability, while precision engineering ensures smooth and continuous rotation. This allows operators to process larger volumes in less time compared to traditional methods. With CE-certified products and patented innovations, SC Equipment emphasizes both safety and reliability, providing operators with confidence that the attachment will consistently perform even under demanding conditions.

The efficiency advantages of a rotating screening bucket are best understood when compared directly to traditional practices.

Aspect | Traditional Screening Methods | Rotating Screening Bucket |

Processing Speed | Slower, requires separate equipment | Faster, directly attached to excavator |

Material Reuse | Often delayed or transported off-site | Immediate reuse on-site |

Equipment Costs | Multiple machines required | One versatile attachment |

Labor Requirements | Higher, multiple handling steps | Reduced, simplified workflow |

Environmental Impact | More transport, higher emissions | Lower transport needs, eco-friendly |

This comparison highlights why the rotating screening bucket has become a preferred solution in projects requiring efficiency and sustainability.

From large-scale infrastructure projects to smaller urban construction sites, the rotating screening bucket offers wide-ranging applications. It reduces waste by enabling the direct reuse of screened materials in backfilling or ground leveling. It also provides significant benefits in recycling and environmental projects, where separating debris from usable soil is essential. With its combination of strength, precision, and adaptability, SC Equipment ensures that each rotating screening bucket delivers measurable improvements in productivity and project outcomes, helping contractors achieve more with fewer resources.